SERVICES

EPDM

24/7

EMERGENCY

ROOF

REPLACE

SHINGLE

ROOFING

WATER

PROOFING

Wolfenburg Roofing

One of the Most Reliable Roofing Companies in Ottawa

MODIFIED BITUMEN MEMBRANES

Modified bitumen membranes are typically used for roof waterproofing in a two-ply

application. The plies of rolled sheets can be bonded by using hot asphalt or fused by

torching the mating surfaces together with a hot flame. Cold applications can be done by

use of Cold Adhesive or by Self Adhesive(Peel Stick) application.

The most prevalent system design using modified bitumen utilizes the membrane in a

fully exposed condition. The membrane is used on occasion in the inverted design or

protected system as well. Modified bitumen is formulated using either Atactic

Polypropylene(APP) or Styrene Butadiene Styrene(SBS) modifiers in combination

with asphalt. The SBS membranes have better low-temperature flexibility and are most common in Canada Modified bitumen membranes are manufactured in rolled reinforced sheets

approximately I meter in width and thickness of 2.2, 2.5, 3, and 4 millimeters

The reinforcement for modified bitumen sheets is either fiberglass or non-woven

polyester. Manufacturers' designations 90, 100, 180, 250, refer to the reinforcement

weight in grams per square meter.

The mopping surface of modified bitumen sheets is sanded while the surface

of the torch grade sheets is a thermo-fusible plastic film. The application is usually done in

two layers, a base sheet, which has no granule protection on the topside, and a cap

sheet, which does have granule protection on the top

Advantages and Disadvantages

PRIMARY ADVANTAGES of modified bitumen membranes are

1. Excellent flexibility

2. High strength

3. High puncture resistance

4. Year-round application (cold process applications are restricted to +5 degree C)

5. Variety of colors

6. Lightweight

7. Excellent weathering

EPDM

Ethylene-Propylene-Diene-Monomer (EPDM) is a single ply sheet membrane used for roof waterproofing by reliable roofing companies in Ottawa. It can be used in a variety of system designs, and can be fully

adhered, inverted and loosely laid and ballasted. The sheet in its final form is a

combination of the rubber polymer(EPDM) and other components including carbon

black. The sheet is typically manufactured non-reinforced, in a thickness of 45 mils, 60

mils and is now available in 90 mils. Some manufacturers produce a polyester

reinforced sheet for use in a mechanically fastened system. Flashings for detail work are

formed with semi-cured EPDM, which can be molded to fit the contours of corners and

other flashing shapes. Bonding of EPDM rubber is accomplished by roofing contractors in Ottawa with the use of adhesive and seaming tap.

Advantages and Disadvantages

PRIMARY ADVANTAGE of EPDM are:

1. Excellent water resistance

2. Excellent weather resistance

3. Excellent heat resistance

4. Good acid and alkali resistance

5. Excellent flexibility

6. Affordable

TPO

THERMOPLASTIC POLYOLEFIN TPO is a thermoplastic* single-ply membrane

used for roof waterproofing in a variety of system designs. It can be adhered mechanically fastened or loosely laid and ballasted. TPO is manufactured in sheets that

are reinforced with a polyester mat. Widths, 8, 10'AND 12' Standard length

100'roll. Thickness-(mils) 45, 60, 72, and 80.

Colors- White, Gray, and Tan.

Manufactured to ASTM D 6878, Specification for Thermoplastic Polyolefin Based Sheet Roofing Plastics.

TPO Accessories

Detail work is commonly done with a non-reinforced product

Preformed Accessories are available in non-reinforced products and now are also

available in reinforced products

Advantages and Disadvantages

PRIMARY ADVANTAGES of TPO:

1. Cost

2. Resistance to acid and alkali chemicals

3. Long Lasting

4. UV Coated

5. Fewer welded seams with wider rolls

6. No Open Flames

7. Easier to Detect Leaks In Future

INSULATION

Insulation performs two functions in a roofing assembly. The obvious use is its role in

reducing the heating and cooling loads on the structure. The second and certainly every

bit as important use is its function as a substrate to support the roofing membrane. In an

inverted membrane assembly, the insulation is a substrate for the ballast and a protection

layer for the membrane. There are numerous roofing insulation products on the market

and as with all material products, the various insulations have their advantages and

disadvantages.

The insulating value of a material is measured in terms of its"R" or"RSI" value R

being a value in imperial measurement and RSI being its metric equivalent. RSI or R

-value is a measure of a materials ability to restrict the transmission of heat and is stated

relative to the thickness of the material

The second property of insulation, its role as a substrate, is much harder to quantify

This property has many components and unfortunately for some insulation

manufacturers, the true ability of their product to perform in the role only becomes evident after several years of service. Insulation must be mechanically stable to prevent

curling and shrinking and must be strong enough to support traffic loads

insulation Properties

The properties that insulation should possess, especially if it is to be used in an exposed

membrane, warm deck roofing system are:

-

High resistance to heat flow -to reduce heat losses from the building(high"R use)

-

Dimensional stability -to minimize volumetric change due to variations in temperature and moisture content. Lightweight- to minimize dead loads(loads due to the weight of structure). Shear strength -to resist deformation.

-

Impact resistance -to provide a stiff support for the membrane and resistance against indentation or puncturing

-

Durability- especially with regard to moisture(wetting and drying) and thermal cycling

-

Fire resistance-to meet Building Code requirements

-

Chemical stability -to minimize future problems with curing

-

Compatibility with other materials used in the roofing assembly

-

Surface smoothness- to provide a satisfactory surface for application of the membrane.

-

Compressive strength- to resist traffic.

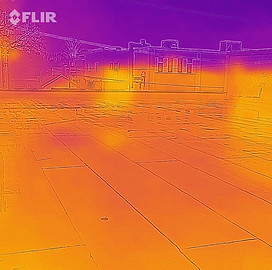

THERMAL IMAGING

Thermal imaging cameras allow us to see if there is any excess moisture trapped under your flat roof. Not only does it indicate if there is moisture, but it makes it easier to determine the source of your leaky roof. Thermal imaging is able to capture infrared radiation which is a part of the electromagnetic spectrum that is not visible to the naked eye. Wolfenburg Roofing uses thermal imaging cameras to scan the roof to better locate water damage, without puncturing or causing any damage to the roof. This method is highly effective and efficient.